Ecrup(Shenzhen) Co.,Ltd

E-mail:ecrup0001@163.com

Mobile phone:15975757675

Website:http://www.ecrup.com.cn

Address:Han Dong Industrial Park, 43 Tong

song Road, Tangxia community, Yan Luo

street, Baoan District, Shenzhen

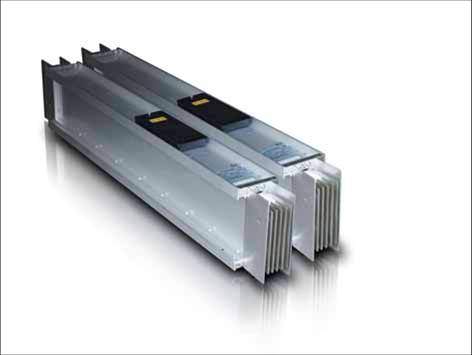

Busbar system

LB bus is mainly composed of the following components:

1 . convenient installation of high strength aluminum alloy

2 . full-length reliable connected aluminum alloy

3 . double torque single bolt connector

4 . high conductivity copper or aluminum conductor

5 . patent technologies socket device

6 . high protection ( IP65) device

7 . with the operating handle and a mechanical interlocking socket box

Bus body

LB bus bus standard surface treatment : LBA row aluminum bus bar copper tin, tin copper bus bar LBC, can also be based on user requirements by silver plating;

Bus with class B insulation materials ( rating of temperature130 ℃) polyester film coated, and reaching the 6 layer, ensure the reliability of insulation;

In addition to plug-in bus socket sites, LB bus using a dense structure, reduce the system impedance;

Provide good outer shell for P E system, reduce customer engineering cost.

Connection device

The busway connector using a single bolt, laminate for high strength aluminum alloy, disc spring ensures that the pressure in the pressure outside the circle on the surface of uniform distribution, and anti-loosening effect;

Bolt double-headed design, installation is only needed when an ordinary wrench wring external screw head can ensure the mounting torque;

Only from one side of the slot to the fastening bolt;

You can not affect the adjacent bus bar slot, dismantle connector;

Flange type structure, and a sealing pad system to ensure the high protection grade.

Shell

Bus groove shell adopts the high quality aluminum alloy, in order to reduce eddy current loss, surface using epoxy resin powder;

The busway enclosure assembly with sealing gasket, ensure the high protection capability; the top surface of the bus bar and the bottom surface of the aluminum alloy extruded sections, high strength, and is favorable to the installation location.

Tapping device

3metre standard straight busway double-sided tape jack up to10 sockets, convenient user multi-point grounding; jack seat and the bus body production

The sealing gasket seal, to ensure a high level of protection;

All socket can be used simultaneously. Connection box with a circuit breaker, a knife fuse switch and fuse type, high, low, and in3breaking capacity seletion;

Connection box operation can select box, outside the box and connecting operation operation operation in 3 ways, to meet the different needs of customers. Linkage operation method can be used for customer operated on the ground socket box.

Connection box grounding pin in line without contacting the bus before and parent line groove ground row of contact, ensure the safety of operating personnel;

The inserting box is arranged in the protective plate to prevent open when the box door and the electric shock;

Connection box valve has interlocking function, to prevent a charged state open valve;

Connection box lock pin with interlocking function, to ensure that the connection box is fully inserted before the closing.

Shell PE, insert special built-in PE row, guarantee the grounding short circuit capacity.